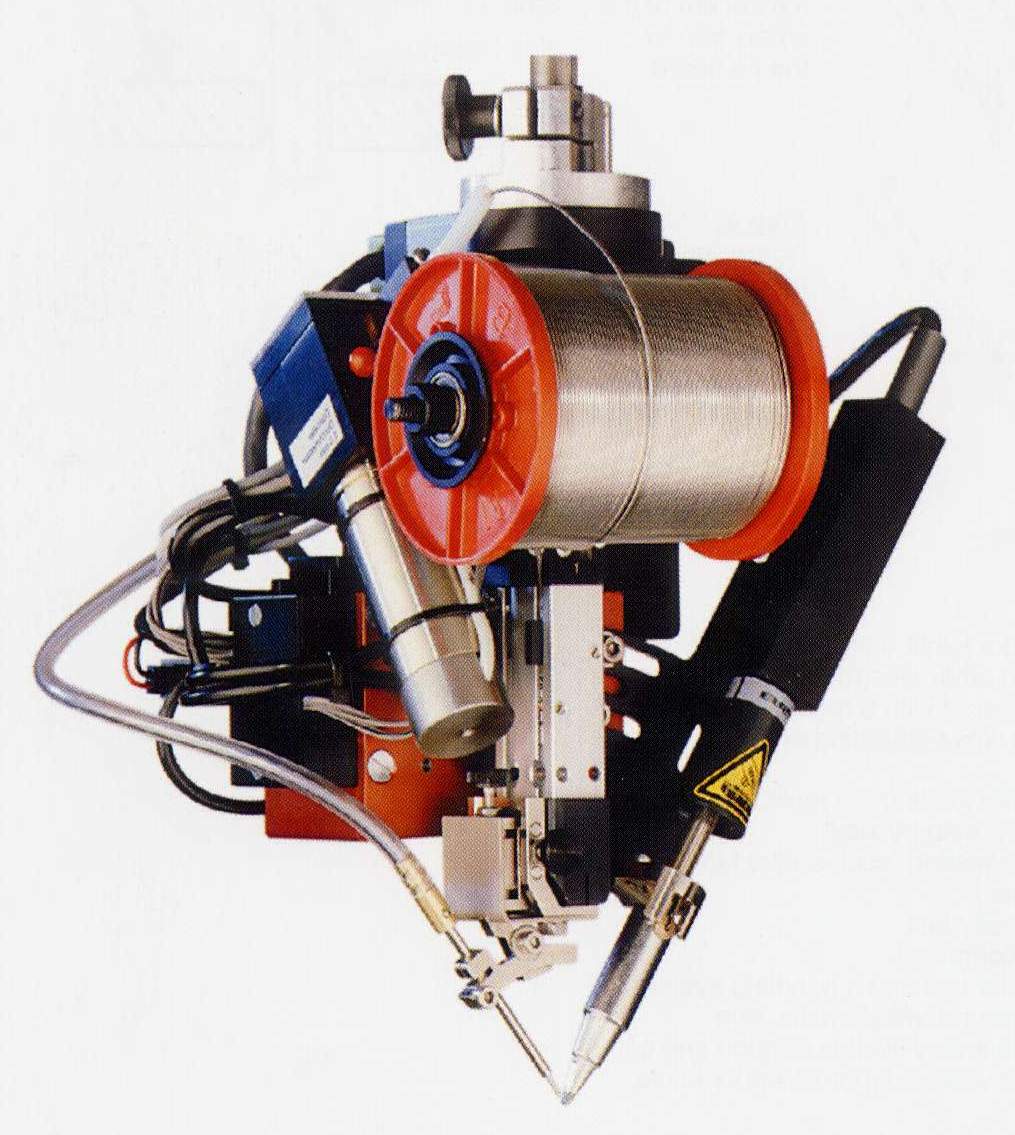

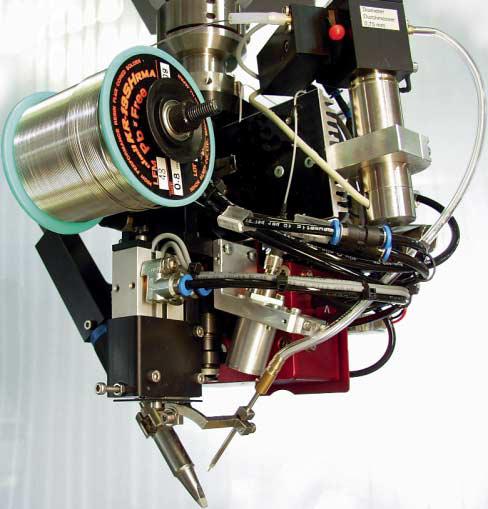

The soldering iron is equipped dedicated calibrated solder tip.

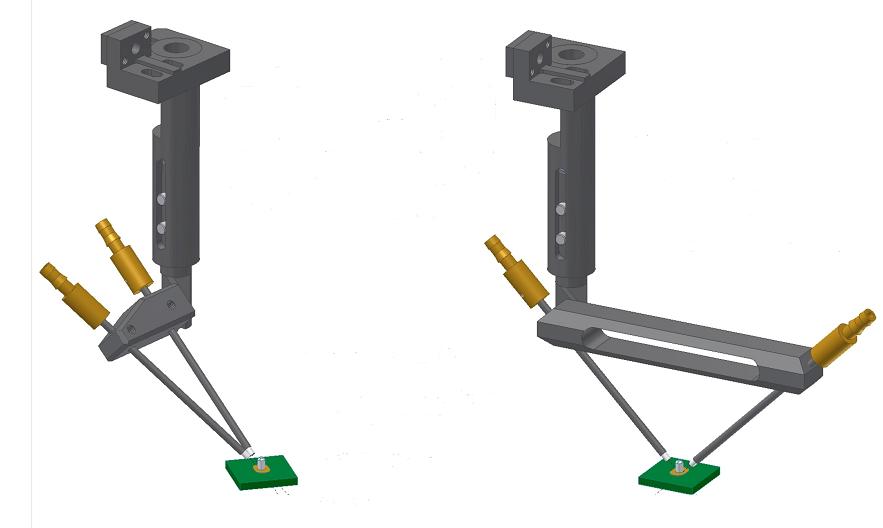

These robots

are suitable for soldering wires, through hole components or SMT.

The

distribution of the alloy is made by the wire coil.

1. Robot ergonomic

2.

Quick step / dual pos

head model

Heads are compatible with both robots and Skyline BoxLine

Mechanism allows controlling the position of tin wire from the failure.

This

eliminates the wire feeding errors due to positioning tolerances of the

part to

be soldered.

The system automatically detects the presence of pin of the

component.

This approach mechanism of the tip and the wire

quick step/dual pos

is a technology patented by Wolf Production Systeme GmbH.

Two cameras viewing in real time the soldering process.

Optionally, an additional camera automatically controls the joint quality .

Features

:

;

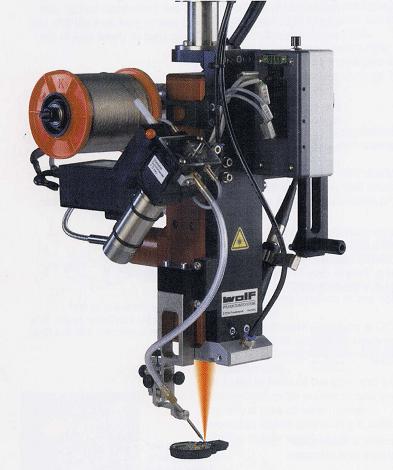

QuickStep - Dual Pos description

Pre tinning on tip

Pre heat of the PAD

Contact tip and connexion

Downhill wire to low position

Advance wire opposite side of the tip

![]() Brochure soft soldering robots

Brochure soft soldering robots

![]() Flyer soft soldering robots

Flyer soft soldering robots

soft soldering robot

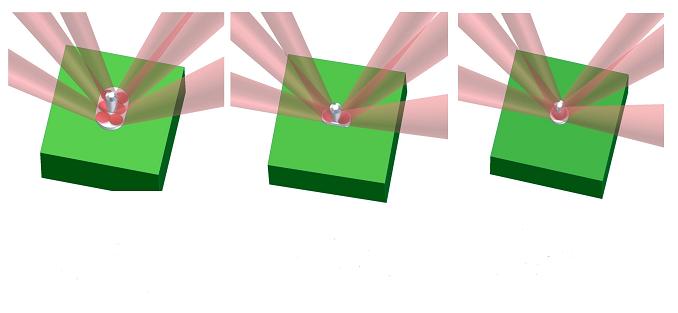

Laser soldering is suitable for many types of applications:

SKYLINE model

head 4 axis (X=500mm / Y=500mm / Z=50mm / ROT=345°)

Toutch screen monitor

PLC Siemens

Loading parts

:

- opening door

- round table

- transfer line

Model Skyline in line

Brochure laser Wolf

![]() Download PDF format

Download PDF format

This laser application is to weld plastic parts.

The laser optic is fixed. Le laser is a powerfull diode laser.

The laser shape is generated through a scanner

galvanometric with

mirrors.