!! Production et distribution interrompue !!

The Exclusive 3D & 2D Solution for Offline Machines

It widely known that 2D machines detect less than 85% of the defects. On

the other hand there are no offline machines aside from ALeader that are

compatible with 3D technology.

As a matter of fact, should a customer would like to have an offline

machine that will detect all defects, his only option would be ALeader

AOI.

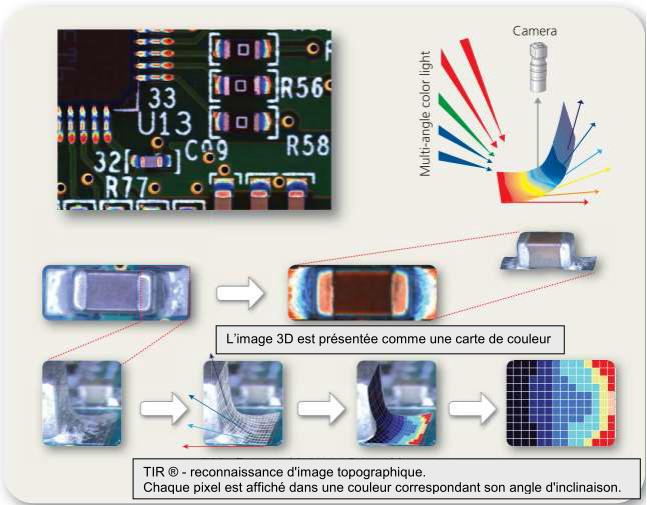

ALeader is the industry pioneer of optic technology incorporating costs

of offline and machine with i3D technology

A multitude of choices in cameras and lighting levels make it a system of high accuracy and speed of inspection.

Specific configurations and different updates are also possible.

|

|

|

ALD 525 i3D is designed for low volume high mix production.

System can be programmed quickly and is able to detect all kind of defects including small chips defects, lifted pins, all kind of solder joint defects and many more. The system includes verification SW and SPC. |

ALD8700 Pro represents the latest generation of the popular ALD AOI

family.

State-of-the-art i3D Technology, which includes high speed digital camera and multidirectional lighting module, is now enhanced with the newly developed grid laser measurement system and camera on-the-fly technology. Supported by the powerful algorithms it delivers unprecedented high speed performance giving no escapes and very low FA rate on the most complicated and challenging PCB assemblies. |