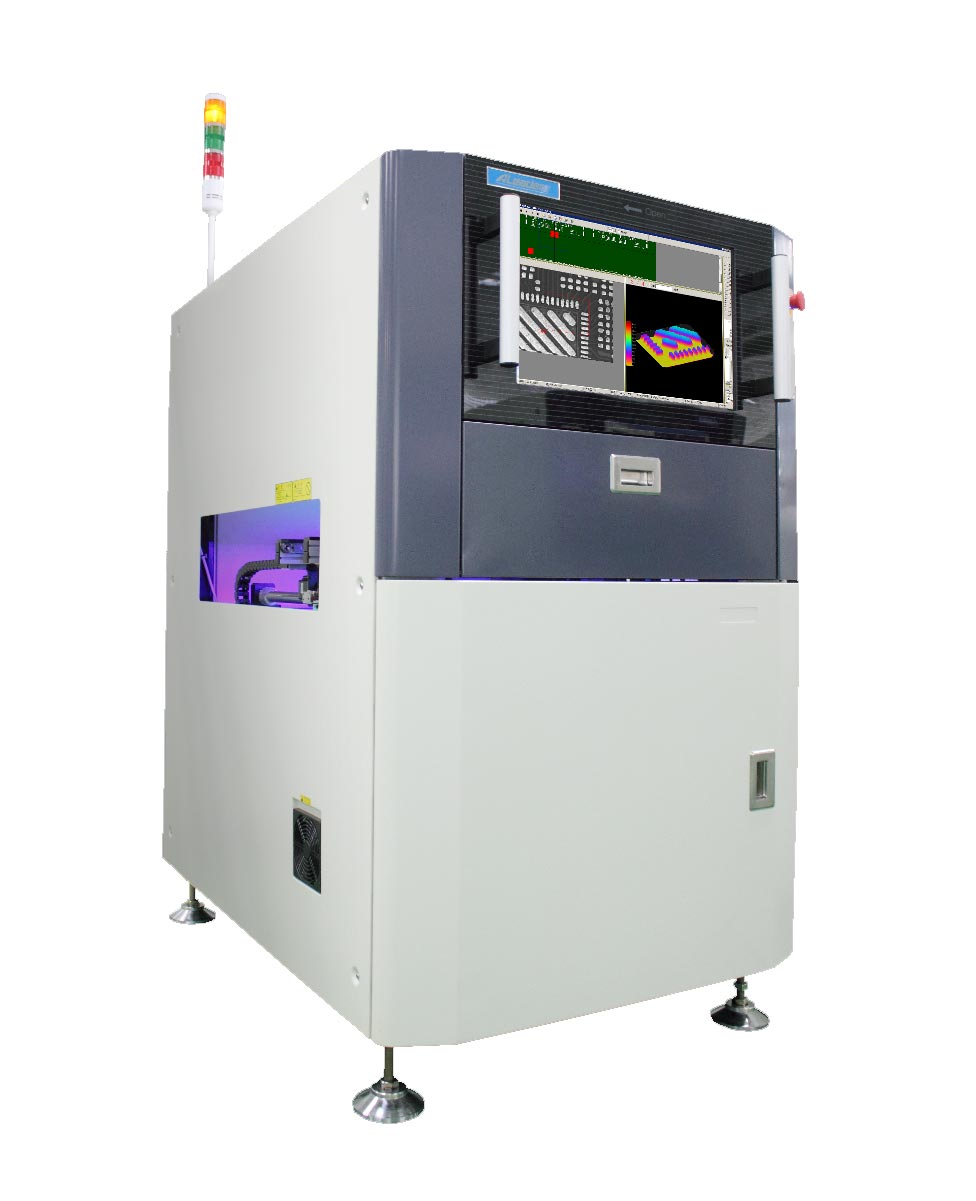

ALeader's iSPI is based on innovative iSPI technology.

It produces the lowest false calls rate of all solutions available on the market, with the benefit of an intuitive programming method that is completed within an unparalleled short period of time. ALeader's iSPI was designed as an affordable machine to provide customers with the highest performing solution at about half the cost of conventional SPI.

Although more than 60% of process defects originate in the printing phase, the modern production printing process is still much more stable than in the past. Modern printers and modern solder pastes are of much higher quality;

however, the challenges are now greater as pads and components are becoming increasingly smaller and more expensive.

Often, repairing PCBs presents a challenging task, compounded by the fact that the cost of each assembled PCB is much higher. Therefore, the conclusions are:

ALeader's iSPI is an affordable SPI that provides all the advantages of conventional SPI, plus many more. Its main advantages are:

Clear, color high resolution 2D image, PMP-based 3D precise height and volume

measurement,

high speed, 100% inspection coverage, less than 3 min programming time,

standard library, warning system and sophisticated process control – all this

makes ALeader SPI a true leader in the solder paste inspection

VIDEO SPI ALEADER