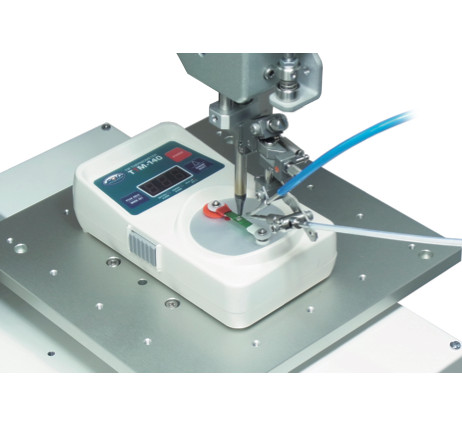

We offer 3 units, one for point soldering and 2 for slide. It takes 8 seconds to replace an iron cartridge and does not require position adjustment upon iron cartridge replacement. The solder feeding position can be precisely set by adjusting the set screw.

This unit can achieve high speed point soldering. The slim design makes it possible to solder applications with tight accessibility issues. This unit has both a pre-feed and secondary feed height adjustment.

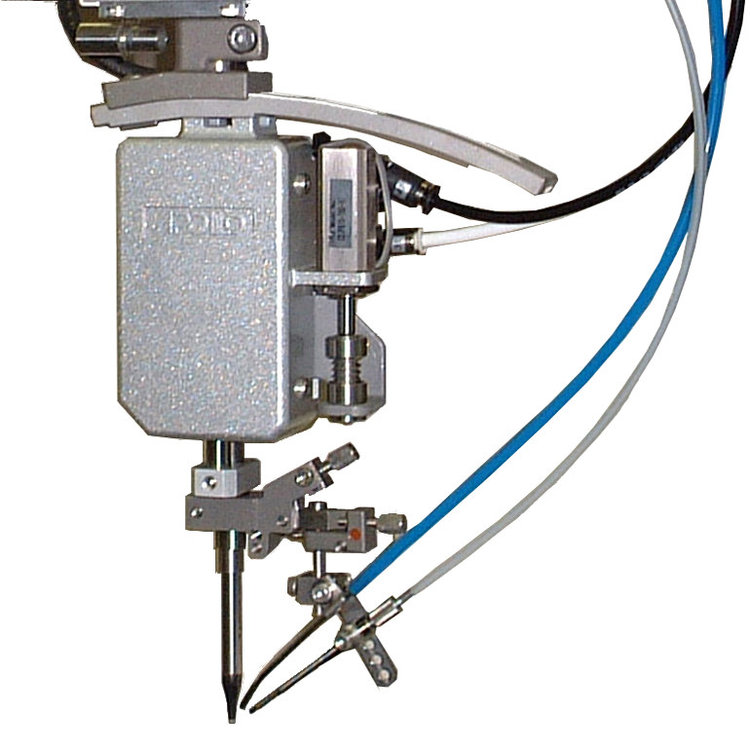

These iron units are designed for slide soldering. The spring loaded tip assembly will not damage PCB solder mask during the slide operation.

The presence of solder balls during the soldering process are a primary cause

of rework and inspection complications, especially in fine-pitch applications.

Apollo Seiko's ZSB feeder system eliminates those issues by combating solder

ball formation from the start.

The built-in roulette cutting blade makes evenly spaced holes while precisely

feeding solder wire.

During soldering, flux is released evenly through these holes, providing

consistent flux coverage without spattering.

The result: solder melts smoothly onto a clean, active surface.