![]() Brochure Solder Feeders SSA SSB ZSB LFD

Brochure Solder Feeders SSA SSB ZSB LFD

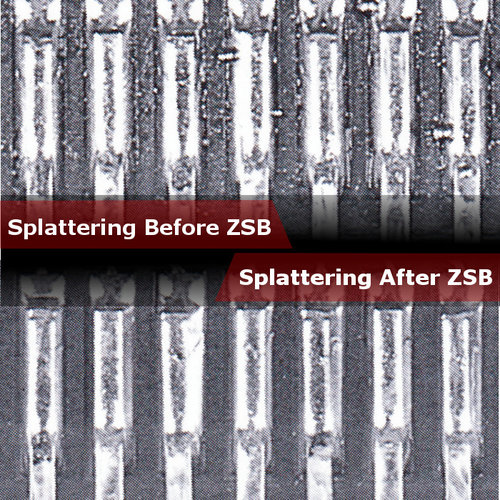

Exclusive Apollo Seiko ZSB feeding technology allows for the elimination of

soldering defects by pre-perforating solder wire to allow for better

out-gassing of the flux core.

Our built-in roulette cutting blade makes evenly spaced holes while precisely

feeding solder wire. During soldering, the flux is released evenly through

these holes. This provides consistent flux coverage without messy spattering

and allows solder to melt on a clean, active surface.

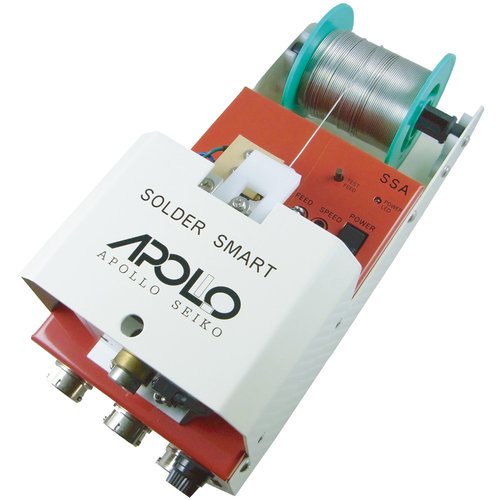

The SSA system is designed for use in automated environments such as filling solder pots automatically, feeding solder for copper joints, flame applications etc. If used to control the solder liquid surface level, it automatically keeps the level constant.

This unit increases the efficiency of manual solder work. Handling the iron

unit and Feeding the solder are two actions that can be done with one hand.

The solder wire feed length is controlled with a timer which provides good

soldering quality, and the iron units can come in either pen or pistol type.

In addition, there are more than 20 different types of iron tips available.

SSB is a soldering iron and solder wire feed function that has been integrated.

You can select the pen or pistol type depending on the application. You can

also use thick solder wire in the form of F2.0.

SSA et le SSB accept wire diameters from 0,4 mm to 2,0 mm.

These feeding units utilize a set of pinch rollers to feed the wire. The Zero Solder Ball (ZSB) rollers are not available on the SSB.

| Type | SSA & SSB Feeder |

|---|---|

| Power | AC 220 V 50/60Hz |

| Motor | DC 5 Watt |

| Wire diameter | 0.4 to 2.0mm |

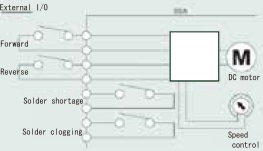

| Feeding type | External control (pulse/continu) |

| Speed forward | 10 to 30 mm/sec |

| Speed reverse | External control : 30 mm/sec |

| Sensors | Clogged / shortage |

| Externam command | Available on SSA |

| Weight | Approx. 2kg |

| Accessoieis included | SSA : connector I/O |

| Option | Output feeding tube |

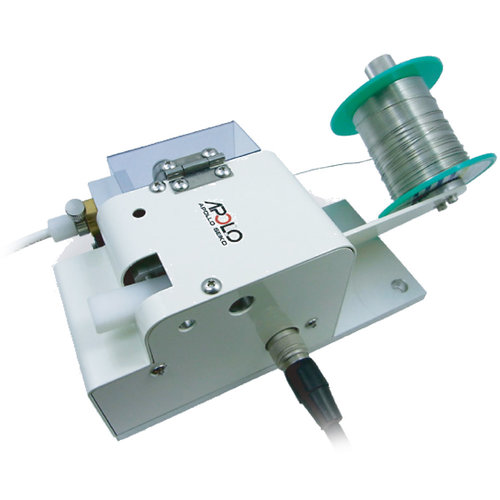

These wire feeders can control feeding amount precisely via its pulse motor. It can also be upgraded with the ZSB roller blade as an optional attachment to prevent solder balls and flux spattering.

ZSB - Zero Solder Ball Feeder

The presence of solder balls during the soldering process are a primary cause

of rework and inspection complications, especially in fine-pitch applications.

Apollo Seiko's ZSB feeder system eliminates those issues by combating solder

ball formation from the start.

The built-in roulette cutting blade makes evenly spaced holes while precisely

feeding solder wire. During soldering, flux is released evenly through these

holes, providing consistent flux coverage without spattering. The result:

solder melts smoothly onto a clean, active surface.

Cette option est intéresante to partir d'un diamètre de fil de

0.5mm

| Type | LFD & ZSB Feeder |

|---|---|

| Wire diameter | 0.4 to 1.6mm (option 0.3mm) |

| Speed forward / reverse | 0.1 to 50 mm/sec |

| Sensors | Clogged / shortage |

| Weight | 1.3kg |