Automatic processing of wire end sleeves 6-12 mm length

Stripping and crimping in one work step

No special tooling for length adjustment required

Quick change of cross-sections with just a few hand movements

High level of reliability due to maintenance and wear-free components

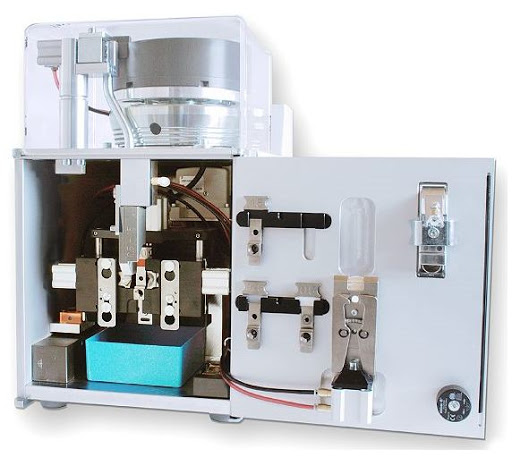

The MC 40-1 provides efficient processing of loose wire end sleeves with

plastic collars in different lengths. This version requires no special tooling

length adjustment. It is simply done by a thumb wheel. The machine features a

high level of reliability and flexibility. The use of premium components in

combination with a robust construction ensures reliable operation.

Cross-sections can be changed quickly with just a few hand movements. After the

wire end sleeves have been changed in the conveyor bowl, only the

cross-section-specific receptacle still just needs to be snapped in and then

production can continue.

For cross sections 4 - 10 mm² (AWG 12 - 8) we suggest the Stripper and

Crimper

MC 40L .