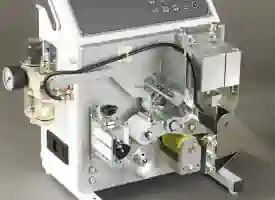

Designed and engineered to meet differing work requirements in a variety of

fields.

Its versatility, technical-functional features and performance capabilities

make it a truly authentic innovation.

It can be used to cut a wide range of materials, for which the manufacturer is

available to carry out test cuts, in order to ascertain the machine

functionality.

Its versatility, technical-functional features and performance capabilities

make it a truly authentic innovation.

It can be used to cut a wide range of materials, for which the manufacturer is

available to carry out test cuts, in order to ascertain the machine

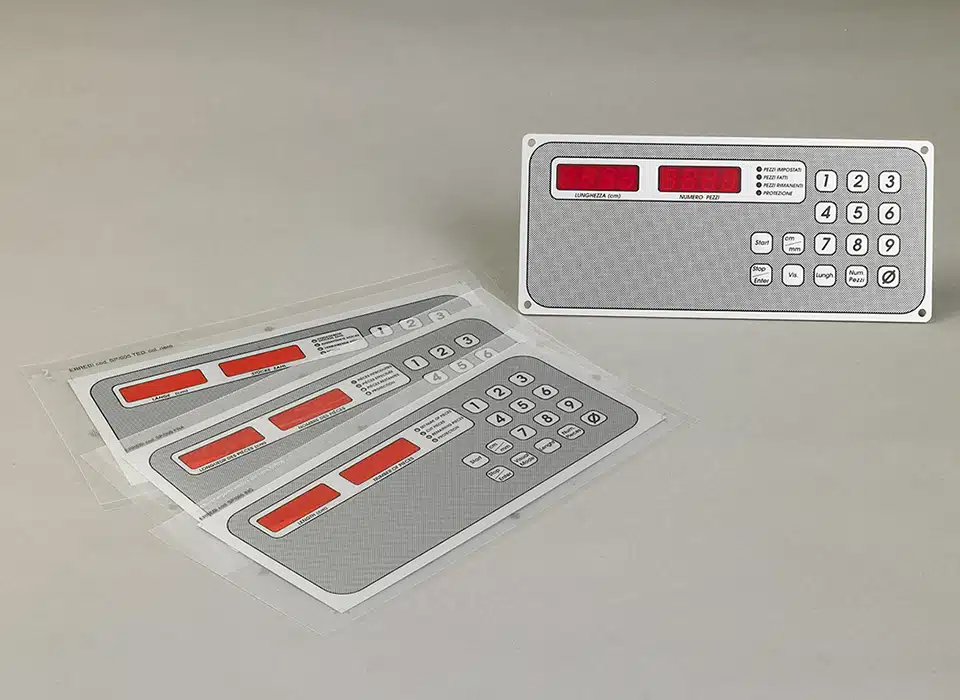

functionality. The automatic operation of the machine is controlled by a

microprocessor, which guarantees the recovery of the work cycle in the event of

a power outage or material malfunction, hence maintaining the residual memory

without the assistance of a backup battery.

The keyboard allows setting and modifying the cutting time as well as the motor

speed, in order to maximise productivity and product quality.

The length and quantity parameters can be set respectively, from 0.1 to 9999 cm

(100 m) and 1 to 9999 pieces (or set to unlimited by using 0 for the number

of pieces).

Upon request, the control panels are available in Italian, English, French,

German and Spanish.

The machine is equipped with safety and accident prevention devices according

to current regulations.

The SP101 STANDARD CUTTING MACHINE is equipped with a tempered steel blade, a

guillotine cut and a cutting aperture of 50 x 20 mm.

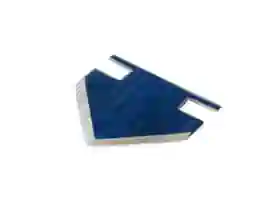

The SPTT pipe-cutting machine is equipped with a V-shaped blade made of

hardened steel.

steel V-blade, for cuts up to 17 mm.

The remarkable cutting force allows processing a wide range of materials,

including:

- Single conductor cable from 0.1 to 25 mm2

- Multi-conductor cable up to 5 x 2.5 mm2

- Flat cables in a variety of sizes

- Tubes, Vipla sheaths, heat-shrink wraps and other materials or wires

Through a simple adjustment to the inlet guiding turret, all the above

materials can be cut without any component substitution, thus ensuring a faster

and more practical operation.

The STANDARD BLADE KIT can be also exchanged with the WIDIA BLADE KIT or the

V-BLADE KIT at any time.

The precision of the cutting length depends on how the material is inserted

into the machine.

When a high-precision cut is required, we recommend using the machine in

combination with one of our DE-REELERS.

SPECIFICATIONS

Control panels are available in the following languages:

ITALIAN Product code: 1010042-IT

ENGLISH Product code: 1010042-EN

FRENCH Product code: 1010042-FR

SPANISH Product code: 1010042-ES

GERMAN Product code: 1010042-DE

Cutting aperture: 50x20mm

Material tempered steel

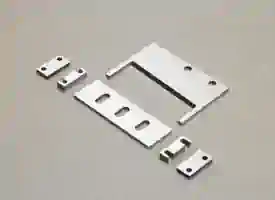

The kit includes upper blade, lower blade, shims and slide guides. Eventual

replacement requires the entire kit and not individual parts

Product code: 1010033

Cutting aperture: 50x20mm

Material tempered steel

carbure widia

plated

The kit includes upper blade, lower blade, shims and slide guides. Eventual

replacement requires the entire kit and not individual parts.

Product code: 1010035

Cutting aperture: 85x20mm

Material tempered steel

The kit includes upper blade, lower blade, shims and slide guides. Eventual

replacement requires the entire kit and not individual parts

Product code: 1010030

Cutting width : max width 50mm, max height 20mm

Material tempered steel

The kit includes upper blade, lower blade, shims and slide guides. Eventual

replacement requires the entire kit and not individual parts

Product code: 1010029

Cutting width : 2×150 mm

Matériau : acier trempé

The kit includes upper blade, lower blade, shims and slide guides. Eventual

replacement requires the entire kit and not individual parts

Product code: 1010031

Includes only the small cutting blade

Product code: 1010028

Cutting aperture : diamètre max 17 mm

Material: tempered steel

The kit includes upper blade and lower blade. Eventual replacement requires the

entire kit and not individual parts. Product

Product code: 1010027

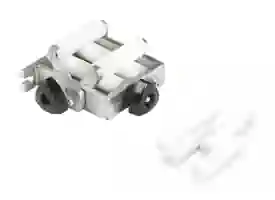

Kit includes four nylon rollers Ø 15 mm.

Product code: 1010022

Kit includes four nylon rollers Ø 15 mm and small blades.

Product code: 1010021

Kit includes a green Vulkollan drive roller and an upper lined drive

roller.

Product code: 1010076

Nylon roller Ø 40 mm, length 40 mm

Product code: 1010056

Nylon roller Ø 40 mm, length 50 mm

Product code: 1010057

Roller with metal core coated in green Vulkollan, Ø40 mm

Product code: 10100455

Roller with metal core coated in red Vulkollan, Ø40 mm

Product code: 1010069

Roller in tempered steel with knurled surface, Ø40 mm

Designed for materials that require greater traction compared to the Vulkollan

roller

Product code: 1010054

Oxidised steel roller, Ø40 mm

Designed for materials that require greater traction.

Product code: 1010070

Inlet air pressure reduction valve with filtering and lubrication zones.

Pipe fittings and pressure gauge are not included.

Product code: 1010075

Inlet air pressure reduction valve.

Pipe fittings and pressure gauge are not included.

Product code: 1010016

Air pressure indicator up to 12 bars

Product code: 1010039

The kit is applied to the cutting machine, to assist problematic materials,

such as very small fragments, exiting the discharge pipe.

Product code: 1010037