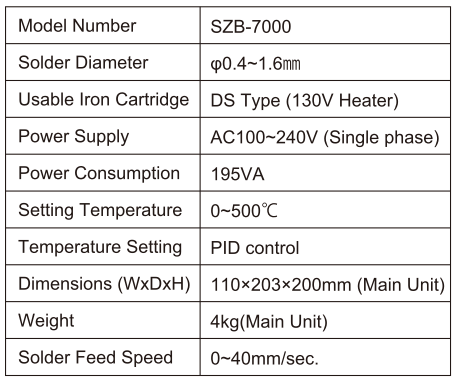

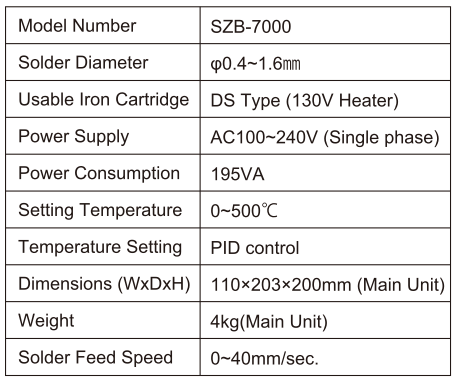

The high-powered soldering station provides 100 watts of soldering power.

The extremely fast heat up & temperature recovery, along with the ability to

integrate N2 gas, make the TTM -3000N ideal for lead free soldering.

The N2 gas can be pumped directly into the TTM-3000N via APN-05 generator or

factory supplied Nitrogen.

Statistical temperature data can be downloaded to a PC using an optical USB

cable.

This station can be equipped with an automatic solder wire feeder mechanism.

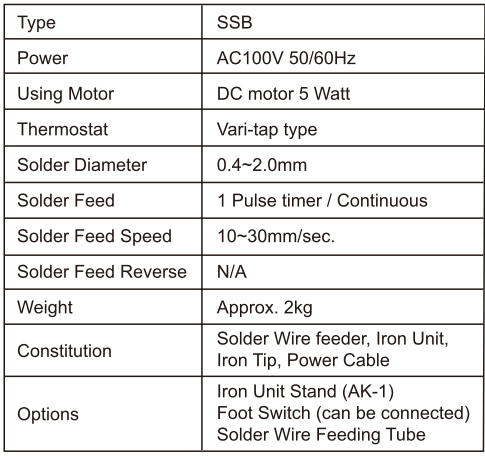

![]() brochure SSB Apollo

brochure SSB Apollo

This is the integral unit to increase efficiency of manual solder work.

Handling the iron unit.

Feed the solder workers can make these actions with one hand.

As the solder feeder feeds a given quantity of solder if using the timer

control, it contributes to stable quality.

There are two choices of iron unit, pistol type or pencil type.

In addition there are more than 20 kinds of iron tip, and we will propose the

best type.

Iron Unit

You can select the PM Iron Unit or AM Iron Unit depending on the application

type.

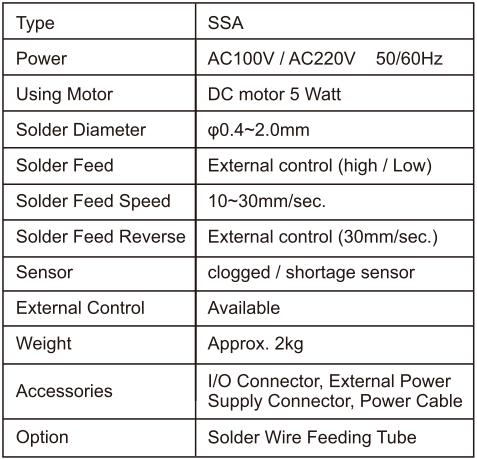

The liquid surface of the solder tank SSA management

You can easily manage the liquid surface of the solder tank using the SSA. The

solder feed and slow switching speed and high speed processing is possible from

external IO. There is also jam detection feature off solder solder, you can use

with confidence.

These feeding units utilize a set of pinch rollers to feed the wire. The Zero

Solder Ball (ZSB) rollers are not available on the SSA or SSB. If this feature

is required, please visit the solder ball reduction section of the ACCESSORIES

page on our site.