- Products

- Robot soldering

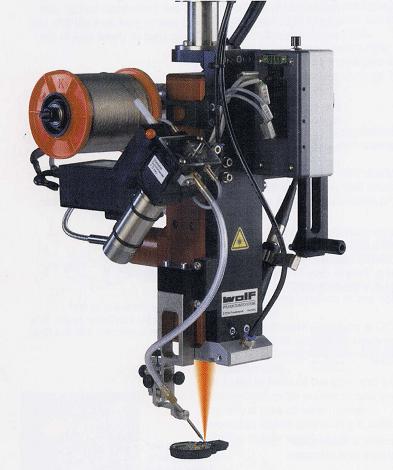

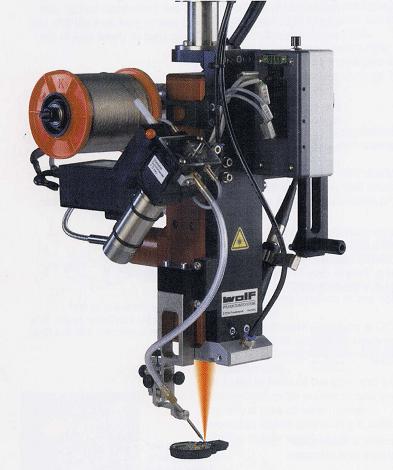

- Wolf laser soldering

WOLF PRODUCTIONS SYSTEMES - Micro laser soldering robotic for electronics

Iron Soldering Robot

Iron soldering

Laser soldering

Laser welding

Iron solder station driven with a 4 axis robotic

Download datasheet

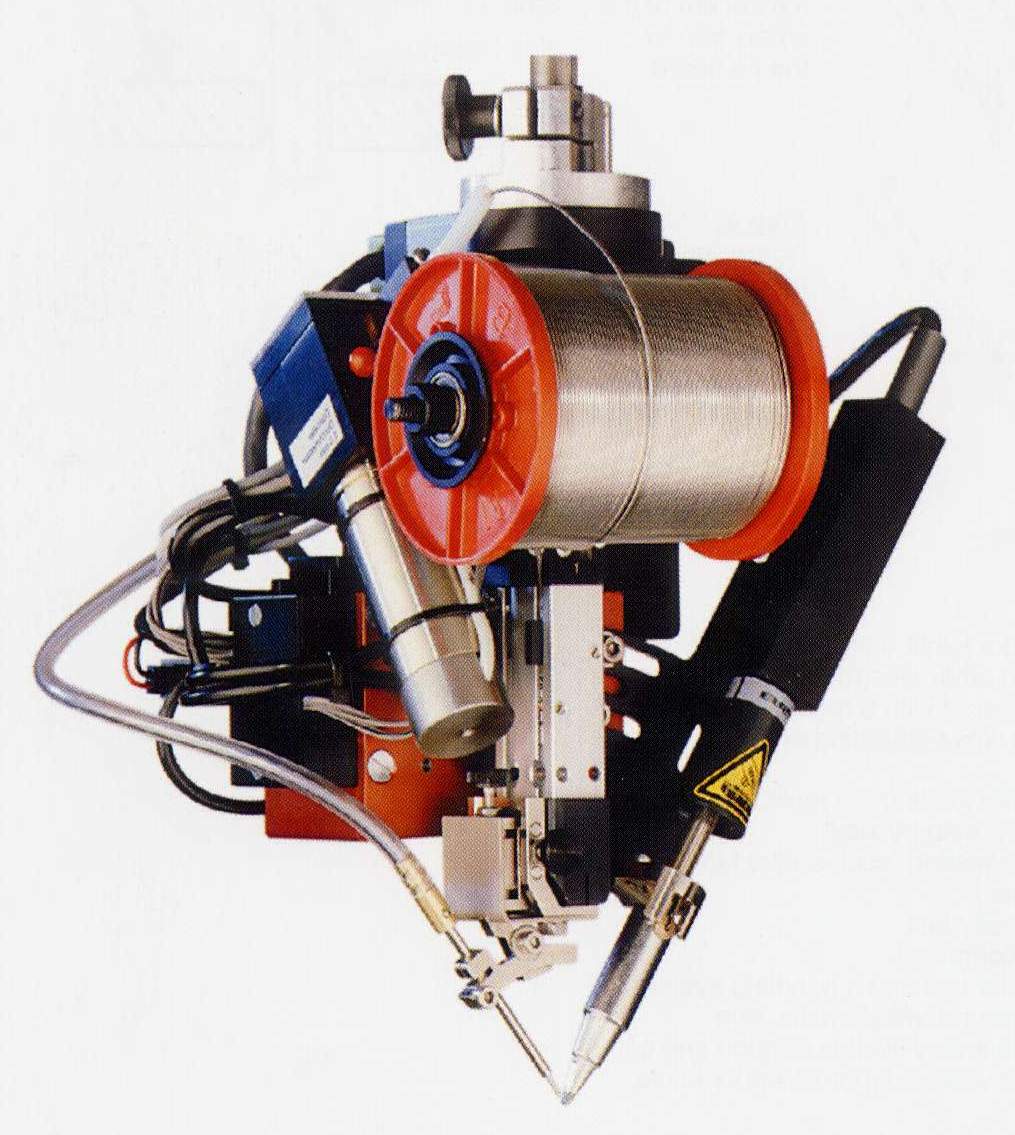

The soldering iron is equipped dedicated calibrated solder tip.

These robots

are suitable for soldering wires, through hole components or SMT.

The

distribution of the alloy is made by the wire coil.

1. Robot ergonomic

SKYLINE model

head 4 axis (X=500mm / Y=500mm / Z=50mm / ROT=345°)

Toutch screen monitor

PLC Siemens S7 or VIPA + software STEP

Loading parts :

- opening door

- round table

- transfer line

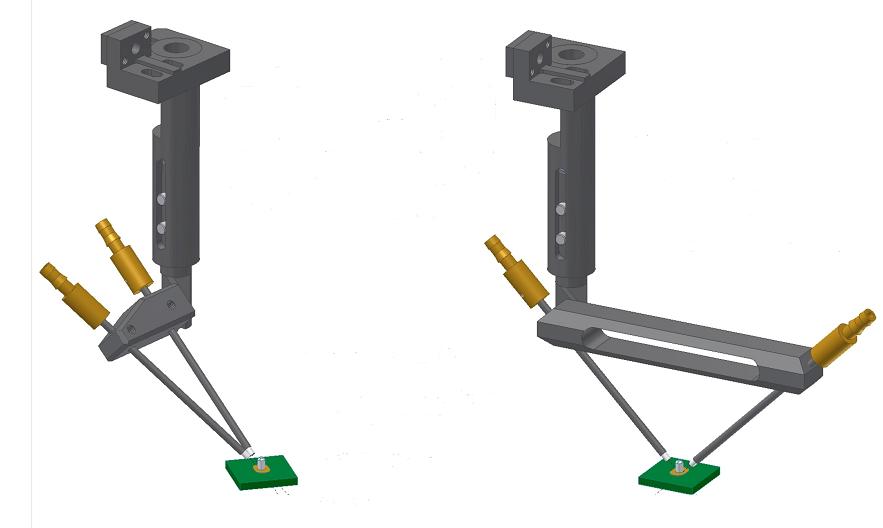

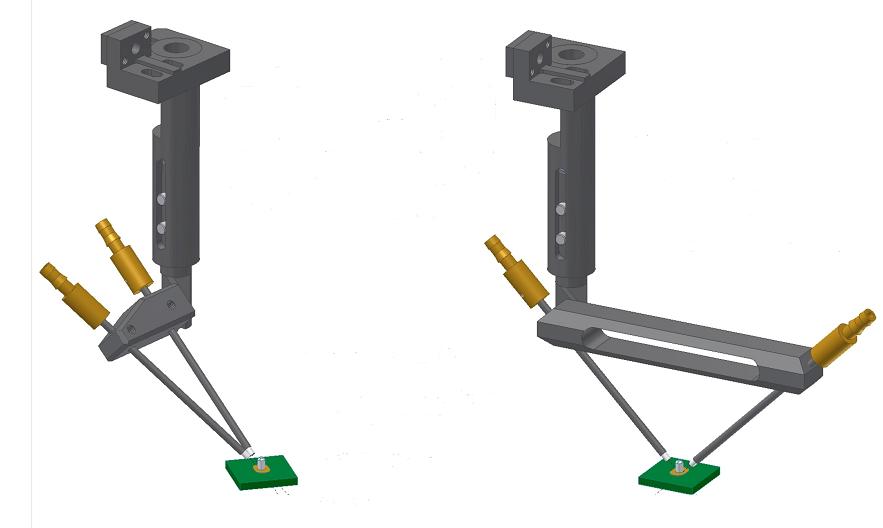

2. Quick step / dual pos head model

Heads are compatible with both robots and Skyline BoxLine

Mechanism allows controlling the position of tin wire from the failure.

This

eliminates the wire feeding errors due to positioning tolerances of the

part to

be soldered.

The system automatically detects the presence of pin of the

component.

This approach mechanism of the tip and the wire quick step/dual pos is a technology patented by Wolf Production Systeme GmbH.

Two cameras viewing in real time the soldering process.

Optionally, an additional camera automatically controls the joint quality .

Features :

Iron power : 120W Head patented "Quick Step Duo Pos" Detecting presence of the pin Long life tip Tip calibrated and enhanced Optimum heat transfer up to the tip Working temperature continuously adjustable Wire feeding by servo with optional encoder Wire feed speed controlled Detection end of wire roll Wire alloy leaded or unleaded Two viewing camera (one vertical and one tilted)

; QuickStep - Dual Pos description

Pre tinning on tip

Pre heat of the PAD

Contact tip and connexion

Downhill wire to low position

Advance wire opposite side of the tip

Laser soft soldering

Brochure soft soldering robots

Brochure soft soldering robots

Flyer soft soldering robots

Flyer soft soldering robots

soft soldering robot

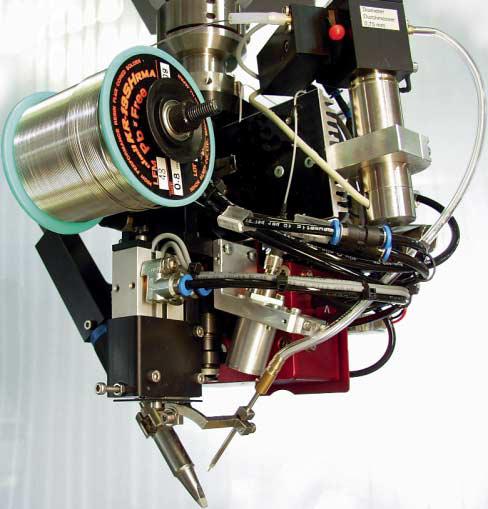

Laser soldering is suitable for many types of applications:

Pins of through hole component,SMT electronics component.

The distribution of the alloy is made by the wire roll. The laser soldering

process allows

accurate and fast soldering. It is perfectly suited to lead-free alloys.

One or two cameras can view real-time implementation of

soldering. Optionally, an additional AOI camera allows for the re adjust

XY robot position before the laser shot and / or automatic control of the

quality of solder joints.

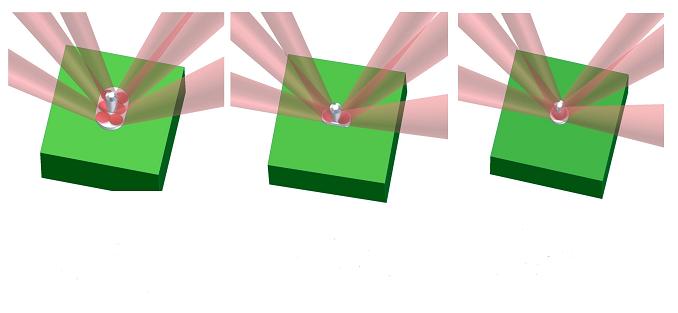

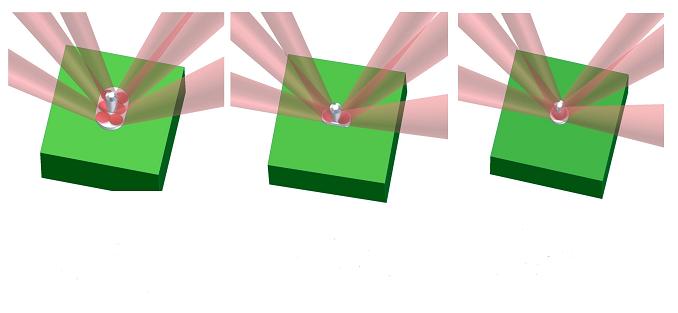

Two laser soldering diodes technology

Laser mono fiber

- Vertical laser spot in 1 point

- Fiber diameter : 0,8 mm

- Diodes life time : 5 000 Heures

- Max. poxwer : 50W

- Single or double solder wire feeder

- Deux cameras

- Option : AOI

Multi fibers laser

Inclined multi fibers laser

- Fiber diameter: 0,2 mm

- 6 diodes 6x10W

- Diodes life time: 50 000 Heures

- Max. power: 60W

- Single or double solder wire feeder

- Deux cameras

- Option : AOI

Focus in 6 points, 2 points or 1 point

Double solder wire feeder

Solder wire diam. 0.5 to 1.5 mm

Micro cut

Connector lead soldered to the laser soldering head 6 beams

- Filling in more than 100% of the via hole

- Crystal structure dense small grains

- Formation of an intermetallic layer thin and uniform

Robots ergonomic SKYLINE model

head 4 axis (X=500mm / Y=500mm / Z=50mm / ROT=345°)

Toutch screen monitor

PLC Siemens

Loading parts :

- opening door

- round table

- transfer line

Model Skyline in line

Brochure laser Wolf

Download PDF format

Download PDF format

Welding with laser scanner

This laser application is to weld plastic parts.

The laser optic is fixed. Le laser is a powerfull diode laser.

The laser shape is generated through a scanner

galvanometric with

mirrors.

![]() Brochure soft soldering robots

Brochure soft soldering robots![]() Flyer soft soldering robots

Flyer soft soldering robots

![]() Download PDF format

Download PDF format