- Products

- SMT capital equipment

- Pick & Place

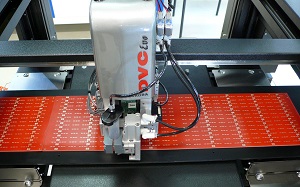

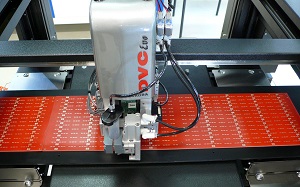

- Quadra DVC evo

PICK AND PLACE QUADRA TWS AUTOMATION

Pick and place robot for electronic PCB board production

Placement machine TWS Quadra DVC evo

TWS Quadra DVC evo dual head SMT placement machine

The Quadra DVCevo (Dynamic Video Centering) machine meets today's requirements for productivity, flexibility and competitiveness.

It enables the precise placement of all types of components currently being wired on SMD boards in small and medium-sized series.

QUADRA DVC evo "Full vision"

SMD ROBOT FOR THE PRODUCTION OF VARIOUS BOARDS IN SMALL AND MEDIUM-SIZED SERIES

FLEXIBILITY / ADAPTABILITY

HANDLING OF EXOTIC COMPONENTS AND ANY TYPE OF SMT LED

CREATION OF CUSTOMISED GRIPPER NOZZLES

0201 CHIP ASSEMBLY

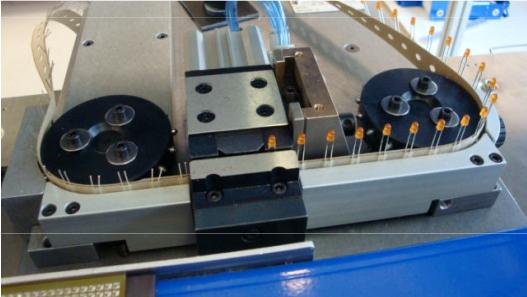

FEEDER FOR TRADITIONAL THROUGH-HOLES THT LEDS

SUCTION TRAY FOR FLEXIBLE KEYBOARDS FORMAT

BRUSHLESS MOTOR TECHNOLOGY

Specifications :

Two simultaneous placement heads

Real placement speed : 3000 cphCentering by 2 DVC cameras"Dynamics Video Centering"Recentering by an external camera for large components

up to 40 x 40 mmOperating system "Linux"Placement to Chip 0201 SOIC, SSOIC, TQFP fine-pitch 0.5 mm, BGA, micro

BGA at pitch of

0.6mm, QFN, PLCC up to 40mm

Melf, mini melf, electrolytic capacitors (H11.0mm max), sot, mini

sot,

exotic componentsThrough-beam LED lamps 3, 4 and 5 mm, round or oval (speed 1800 LED/Hour)Machine resolution +/-0.01mm in XY and 0.08º in rotationRepeatability +/-0.04mm in XY and 0.16º in rotationOverall accuracy +/-0.1mm in XY and 0.16º in rotation Intelligent feedersInstallation of up to 120 x 8mm SMD coils on all 4 sides of the machine

machineIn addition to the above, we also offer a wide range of other services to meet the needs of our customers.

Integrated circuits in strips (stick)Dosing for glue application - pneumatic or

volumetric system with rotary

by rotary screw valveMaximum board size: 440 x 360mm or up to 550 x 420mm with

fewer

feeders

Power supplies: 220V -- Compressed air 60 litres/minute

Ordering reference :Machine: UX0PPDVCETape feeder rack:

KAPPLC5080Stick feeder rack:

KAPPLC8080

Nozzles holder

up to 20 places

Conveyor for large LED PCB

Feeder for TH LED

3, 4 and 5 mm